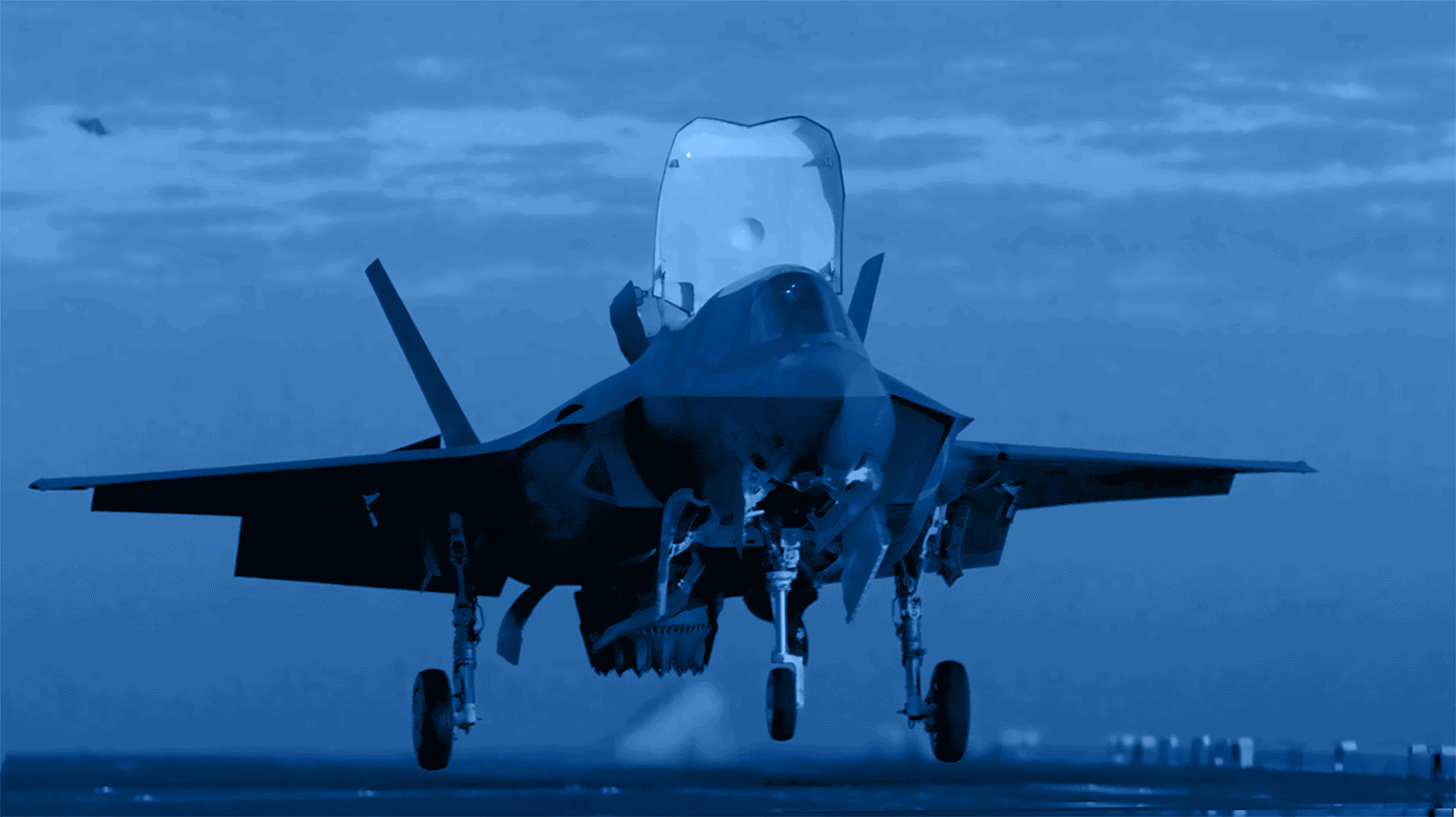

As IT Security departments try to reduce their exposure to attack, intelligence, surveillance and reconnaissance (ISR) missions have been driven to higher and higher altitudes in an effort to reduce the risks of detection and the potential of being a target. In order to compensate for the higher altitudes involved, greater image quality is required. In the face of technological advancements, working with reduced military budgets, and aging systems in the field, new ISR applications have to meet schedule and cost constraints while providing increasingly complex computing to intelligence personnel.

Historically, ISR engagements (often involving images or motion video requirements) have had to rely on ruggedized components due to the extremely harsh conditions in which the equipment needs to function and nature of the missions involved. Although some ruggedized hardware exists for older applications, modern military programs require leading-edge capabilities utilizing semiconductor and board solutions that have yet to be manufactured in ruggedized form. Because of the smaller production volume of required components, the lengthy process to manufacture and approve such components greatly restricts the agility of military applications. The option to develop application-specific hardware is no longer practical as custom hardware costs and timelines are rarely acceptable.

While commercial hardware is lower-cost and available off the shelf, it is challenging to deploy at high altitudes because it is not designed specifically to perform in the extreme conditions found in these airborne platforms.

Using a high-altitude airborne application as an example, Atrenne’s supply chain relationships and management practices facilitate a new approach to ISR environmental isolation which takes advantage of commercial components while speeding production, lowering overall cost, and expanding technology options to include the most recent technological advances.

Case Study – Atrenne Solves for Maintaining Military Standard in High-Altitude Electronic Deployments

Atrenne was challenged by a customer/system integrator under a tight deadline and strict budget to develop a high-quality, full-motion video (FMV) processor system.

The requirements included utilizing both commercial and industrial temperature silicon components that would function successfully and reliably under adverse high-altitude conditions, including extreme temperature ranges, variations in atmospheric pressure, and shock and vibration. Because the customer was only able to present high-level requirements, we needed to collaborate with them closely throughout the design and qualification process to determine the final specifications of the product to properly address thermal, vibration, atmospheric, and altitude conditions.

Higher-altitude requirements for this project drove the need for a more powerful PCI frame grabber than was currently available in a ruggedized form factor. This resulted in the use of a commercial product. Using commercial-grade COTS equipment in this adverse environment presented a variety of engineering challenges. The required components were not designed to accommodate the extreme environment present at high altitude. Furthermore, the preferred components were from an overseas supplier and thus needed to be authenticated and fully traceable. Commercial components and boards have indeterminate life cycles, which introduces the very real risk of product obsolescence during the life of the high-altitude program.

The final product also needed to meet rigorous SWaP-C (Size, Weight, Power, and Cost) and MIL-STD (Military Standard) requirements.

Atrenne’s Solution for High-Altitude Deployment of Defense Electronics

Atrenne’s 50 years of building advanced backplanes, chassis, and packaging solutions for rugged, high-performance applications combined with an extensive ecosystem network of partners and vendors, enables a solid approach to problem-solving and delivers a one-stop-shop experience for the customer / system integrator. Our greatest strengths lie in our breadth of engineering talent, Lean manufacturing processes and the employment of a strict functional project management approach.

In evaluating the situation, Atrenne determined the best approach would be to encase commercial hardware in a sealed rugged enclosure. Using COTS hardware would allow the customer to take advantage of cost savings while enabling use of the latest technology. This would enable the system integrator to be more agile and use the most advanced technology commercially available. Atrenne’s innovative solution called for a SWaP-C-optimized hybrid of a commercial and ruggedized high-altitude ISR system that would mitigate any issues introduced by the non-rugged, off-the-shelf silicon components and modules. The ruggedized system would allow for the use of non-rugged COTS boards and many standard components by hermetically sealing the chassis connectors and fibre optic cables.

This approach would allow the COTS components to function in a temperature and atmospheric pressure consistent with a typical lab environment. Our solution also incorporated workmanship standards, emissions and interference testing, and stress tests for vibration, shock, and temperature. With a robust enclosure design, the system was able to meet these requirements by isolating sensitive internal electronics from the harsh external environment. Third-party testing facilities were used to test and confirm that the solution met rigorous MIL-STD requirements, including:

- MIL-STD-461E EMI radiated and conductive emissions – Requirements for the Control of Electromagnetic Interference Characteristics of Subsystems and Equipment

- RTCA-DO-160D – Environmental Conditions and Test Procedures for Airborne Equipment

- MIL-STD-704E – Aircraft Electrical Power Characteristics

- MIL-HDBK-454B – General Guidelines for Electronic Equipment

- MIL-STD-454 – Workmanship standards

- MIL-STD-810G – Environmental Engineering Considerations and Laboratory Tests

Engage with our team to explore how Atrenne’s ruggedized products and solutions including chassis, backplanes, power supplies, and other electronic components, are specifically designed to meet the demands of high-altitude deployment. Our team of experienced engineers works closely with customers to develop customized solutions that meet their unique needs and requirements.