At Atrenne, thanks to our diverse product line and customer base, we have encountered a number of common pitfalls that, unless avoided, can wreak havoc on OpenVPX designs. Of these obstacles, we have identified the four most common. We’ve put together some simple, straightforward guidance to help ensure the success of your new OpenVPX system design.

- VPX is not like VME

One common error results when customers look at VPX and think that it’s just like VME. The fact is that there are significant differences between the two architectures. It is true that, like VME, VPX targets rugged applications. But, VPX is both a much higher performance platform than VME and is significantly more complex.

It is neither safe to assume that any given OpenVPX module is compatible with any randomly selected backplane/chassis, nor that the module will be compatible with another randomly selected module.

OpenVPX modules and backplanes need to be selected carefully to ensure compatibility. Atrenne can help you select the right modules and backplanes for your application.

- Signal Integrity can dramatically impact system performance

OpenVPX requires a whole different level of attention to signal integrity. Failing to diligently address signal integrity can have serious consequences. An example of this is when high-speed serial links that have high bit error rates won’t run at rated speeds (must negotiate down in speed), or in the worst case, don’t work at all! Signal integrity problems can take a serious bite out of your system-level performance.

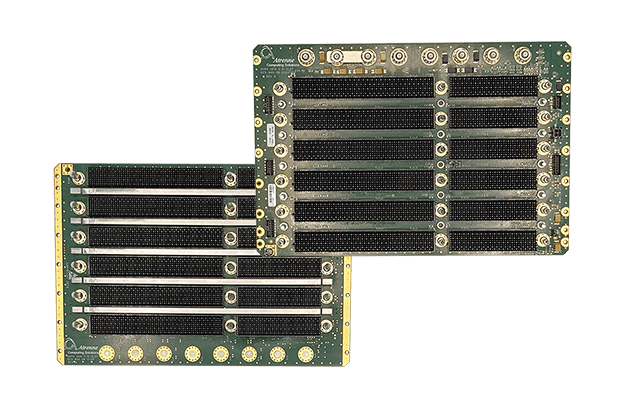

To avoid these problems, Atrenne’s OpenVPX backplanes have always been designed with the highest signal integrity available in the industry. Because of OpenVPX’s dramatically higher speed, significant attention has to be paid to very small but crucial details. This includes use of sophisticated 3D field solvers and simulation tools to ensure that the backplanes will operate at their rated speeds.

Unfortunately, many backplane suppliers and system integrators just don’t have the proper tools and expertise required to ensure successful high-speed OpenVPX communication with low bit-error rates.

- Don’t lose your cool about Thermal Management

Because OpenVPX modules typically operate at much higher temperatures than VME cards, they require much greater attention to thermal management. Failure to do so can result in burning up an expensive set of payload modules due to inadequate cooling. Needless to say, inadequate thermal management can put your program’s overall success at risk.

As with signal integrity, many chassis suppliers and system integrators just don’t have the proper tools and expertise required to ensure successful thermal management of hot OpenVPX payloads.

Compared to OpenVPX, VME64x modules are relatively low power and require only modest cooling; as a result, thermal management is typically not one of the biggest concerns for a VME system.

Many chassis suppliers and system integrators have successfully developed and deployed VME64x chassis without the use of sophisticated thermal modeling and simulation tools, because typical VME64x modules don’t consume a lot of power.

A really hot VME64x module might top out at about 60W. In comparison, for a 6U OpenVPX module, 60W is relatively low power. It’s not unusual for hot OpenVPX modules to consume 2 to 3 times as much power!

Be especially concerned about thermal management when a OpenVPX backplane is being installed into a chassis that was designed for VME64x. Otherwise, the result can be disastrous.

For the health of your payload and your program, you need to ensure that your chassis has adequate cooling. Atrenne can help you select the right chassis with the performance that you need for your application.

- Don’t overlook OpenVPX Profiles

When VME was on the rise, any VME64x card could be used in any VME64x backplane. Even better, all of the VME64x slots had the same pinout for the VMEbus. This made life relatively simple, as a VME chassis could often be used for numerous applications with different payloads

The simple fact is that there is no such thing as a “generic OpenVPX backplane” that is suitable for all applications. With OpenVPX, backplane selection is application dependent.

Say goodbye to VME64x. Say hello to OpenVPX.

With OpenVPX that paradigm is no longer true, and the difference for system designers is game-changing. Many OpenVPX backplanes have slots with different pinouts (e.g. payload slots and switch slots), and different OpenVPX backplanes can have slot pinouts that are different from each other (these are called slot profiles).

OpenVPX Modules are compatible with one or more module profiles. When selecting a compatible backplane, that Module Profile must be compatible with the backplane slot profile.

Also, Module Profile fabric types when using multiple modules must be compatible with each other if they are connected on the backplane. For example, PCI Express® on one module cannot be connected to Serial RapidIO® on another module. In addition, the Module Profile’s fabric baud rate must be compatible with the backplane baud rate. That means that the backplane must be designed to run at least as fast as the speed of the module’s fabrics.

How to ensure successful VME system designs

These issues are a world away from the concerns that face the designer of a VME system. To ensure success, the OpenVPX system interconnect needs to be planned out, and compatible modules and backplanes need to be selected (or developed). The simple fact is that there is no such thing as a “generic OpenVPX backplane” that is suitable for all applications. With OpenVPX, backplane selection is application dependent.

Next Steps

Want to learn more about Atrenne’s OpenVPX implementations for the defense and aerospace industry?

Engage with our team to explore how we can meet your electromechanical interoperability requirements.