Precision Manufacturing for Mission-Critical Systems

Atrenne provides vertically integrated manufacturing services that support the production of highly engineered enclosures, subassemblies, and integrated systems for the aerospace, defense, industrial, and medical industries. Our manufacturing operations are designed to meet the rigorous demands of high-reliability applications, offering a comprehensive suite of fabrication, assembly, and test capabilities under one roof.

With facilities certified to AS9100 and ISO 9001 standards, and processes aligned to IPC-A-610, IPC/WHMA-A-620, and J-STD-001 workmanship requirements, Atrenne ensures quality, consistency, and full traceability across every production phase.

Why Choose Atrenne?

Choosing Atrenne means partnering with a team dedicated to engineering excellence and innovation. Here's what sets us apart:

Machining

Atrenne operates advanced CNC machining centers capable of producing tight-tolerance, mission-ready components from aluminum, stainless steel, and specialty alloys. These parts form the foundation of our mechanical assemblies and ruggedized systems.

Welding

We deliver structural and conductive welds for enclosure frames and internal subassemblies using multiple welding techniques qualified to industry standards.

Metal Forming and Punching

Our metal fabrication capabilities include forming and high-speed punching operations to create chassis components with the strength, complexity, and repeatability required for defense and aerospace programs.

Painting and Plating

Atrenne applies a range of MIL-SPEC surface finishes, including chromate conversion, wet and powder coatings, and specialty conductive coatings. All finishing processes support performance in harsh operating environments.

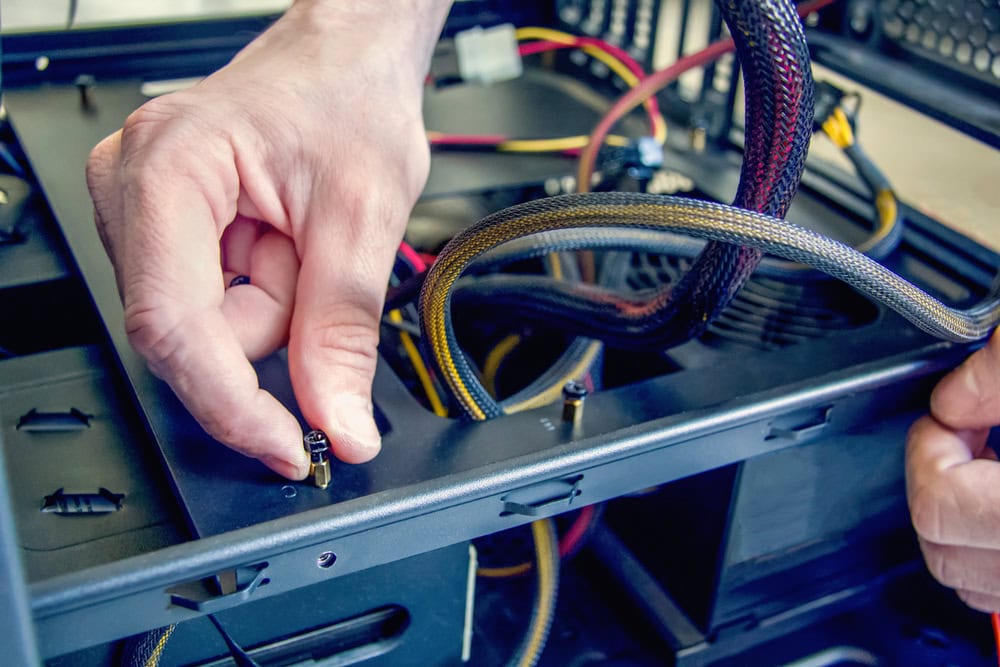

Cable Harnessing

We produce complex wire and cable assemblies tailored to program-specific electrical, mechanical, and environmental requirements. Every harness is tested and documented to meet IPC/WHMA-A-620 Class 3 standards.

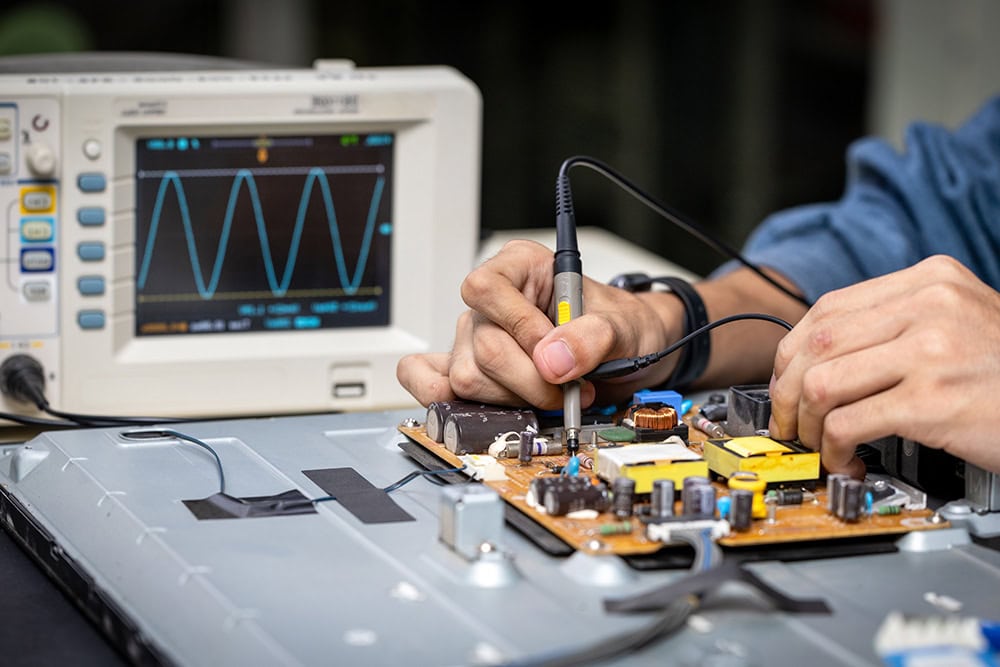

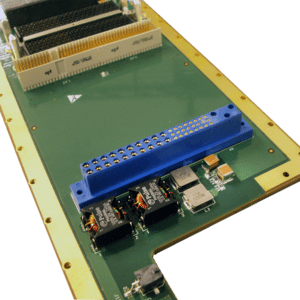

Electronic Assembly

Atrenne provides full-service assembly and subassembly integration, with experience in high-mix, high-reliability electronics. Our processes support a wide range of COTS and custom board technologies.

Environmental Stress Screening (ESS) and Test

We perform ESS—including thermal cycling, vibration, and burn-in—along with full functional and continuity testing to validate system readiness in operational conditions.

System Integration

Our facilities are equipped for full system-level integration and validation. This includes backplane and module installation, wiring, mechanical assembly, and power-on testing. We support both collaborative build-to-spec and build-to-print programs.

Flexible, Scalable Manufacturing

Atrenne's manufacturing model is built for flexibility—supporting low-rate initial production (LRIP), engineering development builds, and high-mix volume manufacturing. Whether delivering standalone chassis or fully integrated systems, we maintain control over quality, lead time, and change management through in-house operations and strategic supplier partnerships.

Our vertical integration enables tight coordination between engineering, manufacturing, and test functions, reducing risk and improving program responsiveness at every stage.

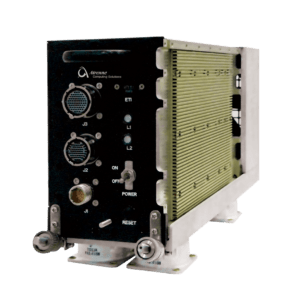

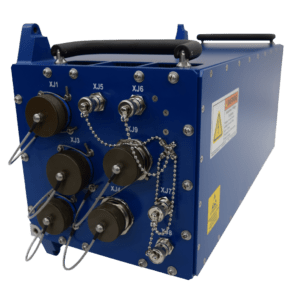

Supporting Advanced Applications

Atrenne’s manufacturing capabilities are applied across a range of high-performance applications, including:

- Embedded computing systems for airborne, sea and ground platforms

- Communications enclosures with integrated thermal and EMI management

- Modular enclosures aligned to SOSA, VPX, VME, and cPCI architectures

- High-speed signal processing assemblies

- Power and control electronics for rail, medical, and industrial systems

Leader in custom-engineered, ruggedized electromechanical solutions, leveraging award-winning 3D aluminum printing technology

A Trusted Manufacturing Partner

With over five decades of experience supporting the world’s most demanding government primes contractors, tiers 2 & 3, and OEMs, Atrenne combines technical depth with responsive program execution. Our teams collaborate from conceptual design to deployment —whether through early supplier involvement (ESI), design for excellence (DFX) consultation, or full-lifecycle sustainment support. When precision, repeatability, and reliability are mission-critical, Atrenne delivers.